Belt Conveyor – IS 11592

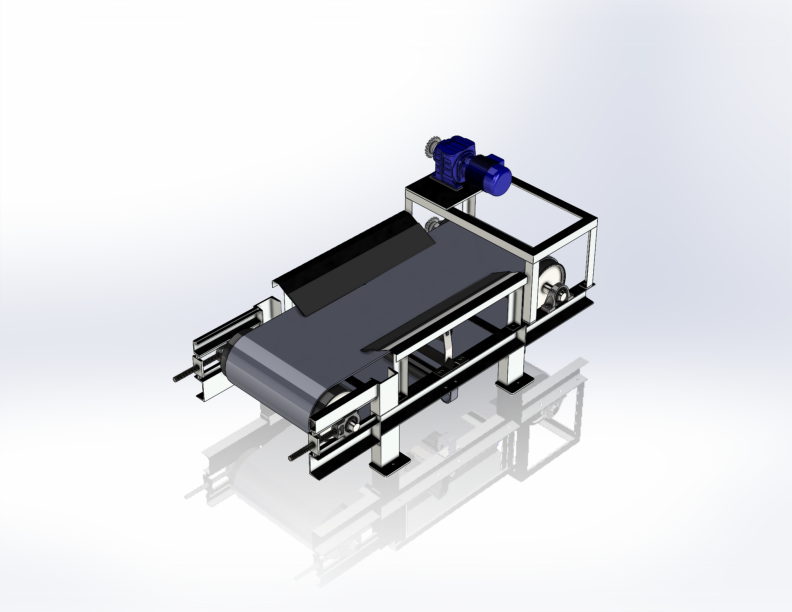

The right material handling system can add automation and fluidity to any application in the Waste Water Treatment Plant & Industries. We offer a wide range of optional equipment to complement our conveying systems in order to provide you with a complete system designed to handle your specific material. All belt conveyors and conveyor systems are engineered around unique application to ensure the best handling solution possible.

Standard troughed belt conveyors are comprised of conveyor belting that rides on heavy-duty troughed idlers. Idlers range in angles from 20°-45° and are securely mounted to a structural steel frame.

These belt conveyors can be run at various inclined angles, typically between 0°-20° (30° with cleated/chevron belting).

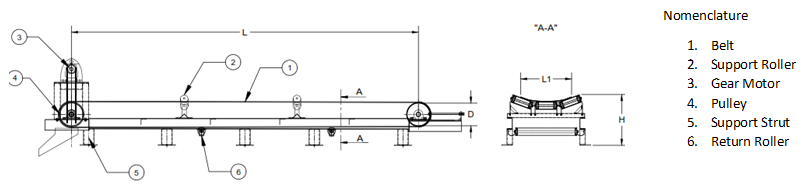

It consist of a structural steel work with a section suitable for the belt sliding, struts of different size for the required frame inclination, a closed loop belt of wear proof material resistant to the atmospheric and chemical agents, a motor controlled roller for the belt driving, a set of support roller and lateral guide for the belt, side boards for the containment of the transported material, a loading hopper and a gear motor.

On request it is possible to provide emergency belt tripper, belt sway switch, Dog box canopy, skirting & deck plates along with belt conveyor.

EXTRA BENEFIT

Belt Conveyor Features

Belt material : Nylon with Neoprene lining

Various belting options

Length : 1500mm to 12000mm

Height: Min 450mm

Size: 500mm – 1200mm wide

Frame Material: MSEP / SS

Custom design for optimal handling

Heavy-duty construction

MAIN FEATURES / Unit / DIMENTIONAL DATA

BELT LENGTH

L

MM

1500 - 1200

BELT WIDTH

W

MM

500 - 1200

BELT TOP HEIGHT

TH

MM

MIn 450