CyclOxy Aspirator

First of Its’ Indigenous Innovation in Aeration Technology – Patented Make in India High Performance & Advanced Jet Aspirator with Superi- or & enhanced Aeration Capabilities for Waste Water Treatment

The CyclOxy Aspirator’s & Aerator’s uniform mixing and Aeration assures that the oxygen is thoruoghly mixed with the waste water in aeration tank. it can be used alone or in combination with other types of aerators (Surface Aerators/Diffusers/Venture Aerators Etc.) to provide optimal effciencies for particular applications.

The standard material for the air jet screw, hollow tube shaft, housing and all submerged parts are in AISI 316. This stainless steel ensures high corrosion prevention and reliabillity in extreme enviornmental conditions. The submerged section does not contain any seals or bearings.

“INNOVATIVE & PATENTED PRODUCT ”

“We are the first company in India who have patent in jet aeration for waste water treatment which is innovative and novel technology in design”

Aspirator & Aerator

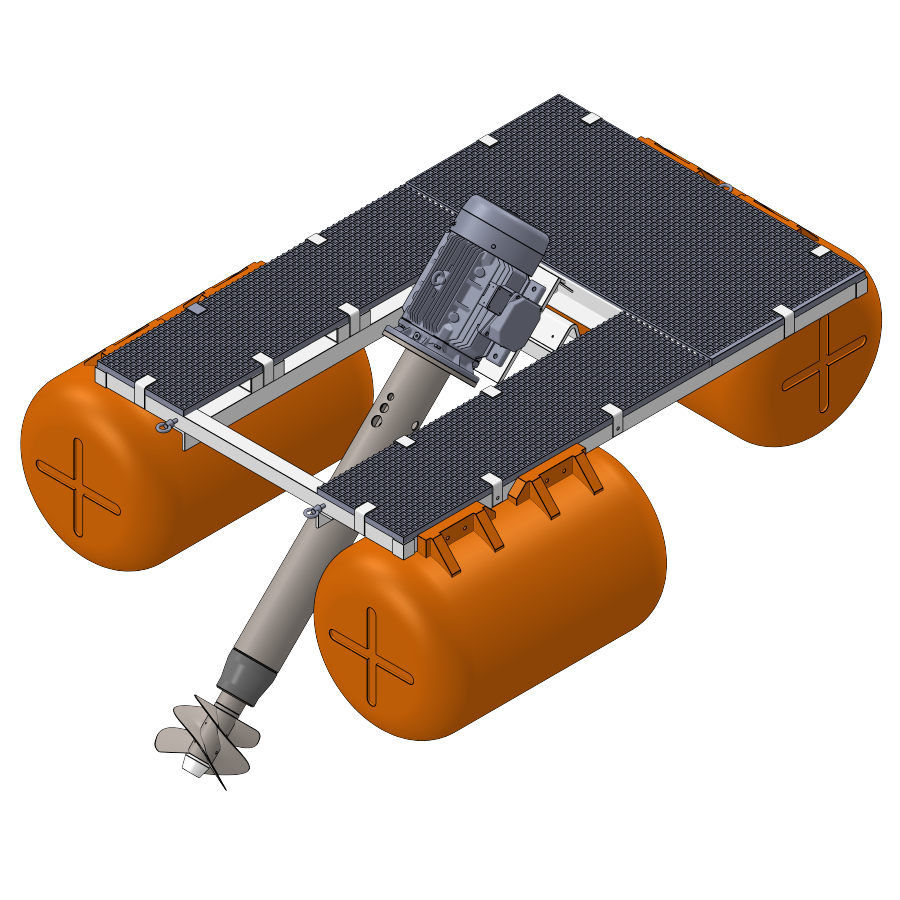

- The CyclOxy Aspirator consists of specially design Air Jet Screw, hollow shaft, motor and housing. The Design of aspirator ensures that the motor and air intake is always above the water surface and the Air Jet Screw is always submerge in the water. As the air Air Jet Screw rotates, it induces a flow of Atmospheric Hollow Shaft air through the air intake ports on the shaft.

- The CyclOxy Aerator’s consists of blower, specially designed airjet screw, hollow tube shaft, motor and cover housing. The design of aerator ensures that the blower, motor and air intake port are always above the water surface and the air jet screw is always submerged in the water.

Working Philosophy

- State of the Art Indigenously Designed & Manufactured Cycloxy™ Jet Aspirator Aerator comprises of high-performance Air Jet Screw, Hollow Shaft Assembly, Housing Assembly & Electric Motor.

- It rotates at 1400 rpm & that creates vacuum allowing atmospheric air to be sucked in through Air Intake Ports open to atmosphere & located on the upper side of Aspirator Housing Assembly.

- Air travels through Hollow Shaft Assembly towards bottom end of Aspirator assembly which is submerged under water.

- The innovatively designed high performance Air Jet Screw pushes the Fine Air Bubbles into the effluent water in forward direction creating powerful mixing and efficient aeration across the span & depth of aera- tion tank.

- The spiral longitudinal and lateral path of fine air bubbles provides optimum hanging time for permitting maximum Oxygen diffusion in effluent water along with superior mixing and high Oxygen Transfer making most efficient aeration ad hence maximized degradation of biological / organic load along with maintaining sufficient dissolved Oxygen in aeration tanks.

EXTRA BENEFIT

Surface Aspirator & Aerator (Features)

Mounting Arrangement: Fix & Float

MOC: SS316/SS304

IE2/IP55 Motor

No gearbox, less maintenance

Uniform dispersion

No Membranes – No Cleaning & Replacement

Oxygen transfer efficiency 1.8 to 2.2 kg 02/kwhr

Available horsepower range 2hp to 60hp