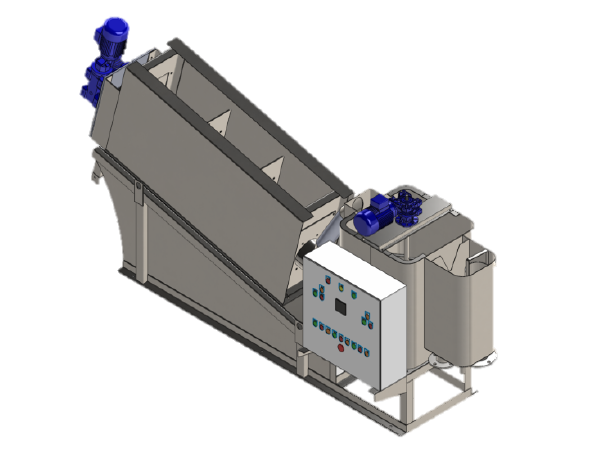

Screw Dehydrator

ArCh Enviro range of Sludge dehydrators / Dewatering screw press is designed to provide 3 functions in 1 unit. Sludge press gives benefits over conventional methods of sludge treatment like Small footprint, low energy consumption.

Can reach outlet sludge consistency from 15-25% And It uses stainless steel discs and screw as the medium.

Dehydrators offers the benefits include a high capacity, Jam/clog free, very low wash water requirement, highly efficient method of sludge/liquids separation.

Screw Dehydrator - Design

- Screw Dehydrator are mechanically cleaned very fine sludge dewatering equipment used to separate sludge and water in sewage treatment plants. These are also ideal for effluent treatment plants of food processing, textile, pharmaceuticals, chemicals, sugar, breweries etc. Each unit is designed carefully as per inlet sludge characteristics based on the application.

- Each unit incorporates a sludge conditioning zone followed by inbuilt sludge thickening zone and dewatering press zone. Screw compresses the sludge and flexi plate offers water to drain out, enabling the separation process.

- This sludge is further compacted by screw and can be taken out in cakes with 75% moisture. Sludge can be further used as manure and can be sold to farmers.

EXTRA BENEFIT

Screw Dehydrator Features

It uses stainless steel discs and screw as the medium.

Material of Construction: Stainless steel 304 / 316

Inlet flow 1% concentration sludge: 0.5 cmh to 25 cmh.

Power requirement: 0.5 hp to 5 hp.